Powering Reliability. Maintaining Excellence

Gas Turbine Accessories

Delivering Excellence in Gas Turbine Accessory Repair and Support

Energy Services: The Most Comprehensive Repair Source for Gas Turbine Accessories

Delivering Excellence in Gas Turbine Accessory Repair and Support

Gas turbines serve as the heartbeat of countless industries, from power generation and oil & gas production to aviation and marine operations. Their reliability and efficiency are paramount, not just for the organizations that rely on them, but for the communities and infrastructures they power. Within these sophisticated machines, accessories such as fuel systems, valves, actuators, pumps, and control modules play critical roles. The ongoing performance and longevity of these components are essential to the turbine’s overall health. Recognizing this, Energy Services has established itself as the most comprehensive repair source for gas turbine accessories, setting industry standards for quality, expertise, and customer satisfaction.

The Critical Importance of Gas Turbine Accessories

When considering the operation of a gas turbine, it is easy to focus on the main engine itself. However, the accessories, those “hidden” yet vital components, are what enable seamless and efficient operation. These include:

-

- Fuel System Components: Fuel nozzles, pumps, and filters ensure proper delivery and atomization of fuel.

- Valves and Actuators: Responsible for precise control of air and fuel flow, contributing to efficiency and emissions control.

- Instrumentation and Sensors: Critical for monitoring temperature, pressure, and vibration in real-time.

- Lubrication Systems: Pumps, coolers, and filters that safeguard bearings and moving parts from wear.

- Electrical and Control Modules: Interface with control rooms or automated systems for safe, optimal performance.

Failure or suboptimal performance in any of these accessories can lead to efficiency losses, unplanned downtime, increased emissions, or catastrophic failure. This makes high-quality repair services not just a cost-saving consideration, but a fundamental operational necessity.

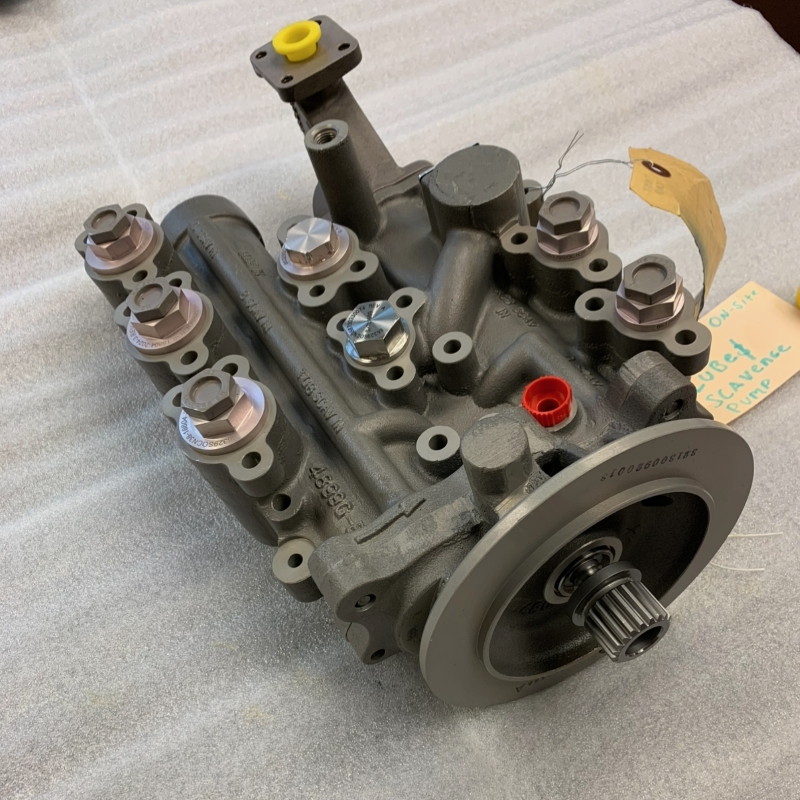

GAS TURBINE PARTS BEFORE REPAIRS

GAS TURBINE PARTS AFTER REPAIRS

Energy Services: A Legacy of Excellence

Energy Services has built its reputation on a foundation of technical mastery, innovative solutions, and unwavering commitment to customer success. With decades of experience across all major gas turbine platforms: Pratt & Whitney, GE, Siemens, Rolls-Royce, Solar, and many more, the company brings a depth of knowledge that is unmatched in the industry.

Comprehensive Capabilities

Energy Services distinguishes itself through its all-encompassing suite of repair and maintenance solutions for gas turbine accessories:

-

- Full-Service Diagnostics: Utilizing advanced diagnostic equipment, including ultrasonic, eddy current, and X-ray analysis, Energy Services pinpoints the root causes of accessory failure and wear.

- Component-Level Repair: Highly skilled technicians perform everything from micro-welding and precision machining to the replacement of seals, gaskets, and bearings, restoring components to like-new condition.

- Upgrades and Modifications: As technology evolves, Energy Services offers hardware and software upgrades for control modules and sensors, ensuring compatibility with modern turbine systems.

- Testing and Calibration: Every repaired accessory undergoes rigorous testing and calibration to OEM or better standards, guaranteeing seamless integration and reliable performance.

- Field Services and Technical Support: For urgent needs, Energy Services deploys field teams to customer sites, offering on-the-spot troubleshooting and repairs, minimizing downtime.

- Inventory Management and Logistics: The company maintains a robust inventory of critical spares and exchange units, enabling rapid turnaround and minimizing operational disruption.

State-of-the-Art Facilities & Skilled Workforce

Energy Services’ repair centers are equipped with cutting-edge technology, from clean-room environments for intricate assemblies to advanced CNC machining for precision part fabrication. The technicians, engineers, and quality control personnel undergo regular training and certification, staying abreast of the latest industry standards and manufacturer specifications.

The company’s investment in digital infrastructure allows for real-time tracking of repair progress, detailed historical reporting, and transparent communication with customers. This ensures that clients are always informed and in control throughout the repair process.

Commitment to Quality and Safety

At the heart of Energy Services’ operations is an uncompromising approach to quality and safety. All repairs are performed in accordance with rigorous internal procedures, relevant industry standards (such as ISO 9001 and AS9100), and Original Equipment Manufacturer (OEM) guidelines. Each accessory is subjected to meticulous inspection, non-destructive testing, and functional verification prior to release.

This commitment not only improves reliability and performance but also helps customers comply with regulatory requirements and minimize environmental impact. An accessory repaired and certified by Energy Services carries the assurance of longevity, safety, and optimal performance.

Benefits of Choosing Energy Services

Selecting Energy Services as your repair partner translates into a host of tangible benefits:

-

- Reduced Downtime: Rapid diagnostics, repair, and exchange programs keep turbines running with minimal interruption.

- Cost Savings: Extending the service life of accessories allows customers to avoid costly replacements and unexpected capital expenditures.

- Peak Efficiency: Properly maintained and calibrated accessories ensure turbines operate at optimal efficiency, saving fuel and reducing emissions.

- Regulatory Compliance: Maintenance and repair records, coupled with documented test results, aid in satisfying governmental and industry regulatory requirements.

- Sustainability: Refurbishment and repair help reduce environmental waste associated with replacement components.

Customer-Centric Approach

One of the defining traits of Energy Services is its customer-first philosophy. From the initial consultation to post-repair follow-up, the company works in close partnership with its clients. Detailed failure reports, maintenance recommendations, and training sessions are provided, empowering customers to make informed decisions and to build internal operational resilience.

Energy Services understands that each client and each turbine installation is unique. Solutions are tailored to specific operational needs, environmental factors, and budgetary constraints. Whether the fleet consists of legacy units or state-of-the-art turbines, Energy Services delivers consistent, reliable results.

Success Stories and Industry Impact

Across the globe, major utilities, independent power producers, and industrial operators have turned to Energy Services for their gas turbine accessory repair needs. Case studies abound where proactive repairs, upgrades, and preventative maintenance have averted costly outages, improved efficiency, and extended the life of critical assets.

For example, a large power plant facing repeated actuator failures found a lasting solution through Energy Services’ custom-engineered repair and upgrade program. Another client, operating offshore platforms, benefited from rapid-response field service teams, restoring critical lubrication pumps and minimizing production losses.

Innovation and Continuous Improvement

The energy landscape is ever-evolving, with new challenges arising from digitalization, decarbonization, and resource constraints. Energy Services remains at the forefront by investing in research and development, employing data analytics for predictive maintenance, and adopting sustainable practices. The company’s forward-thinking culture ensures that customers benefit not only from today’s best solutions but also from tomorrow’s innovations.

Conclusion

In an industry where reliability, efficiency, and safety are non-negotiable, Energy Services stands out as the most comprehensive repair source for gas turbine accessories. Their blend of technical expertise, customer focus, and commitment to quality empowers operators to extract the maximum value from their assets. Through continuous innovation and relentless pursuit of excellence, Energy Services does more than repair components—they power progress and fuel the future of energy.

For those seeking a partner who delivers beyond expectations, Energy Services is the unequivocal choice in gas turbine accessory repair. With Energy Services at your side, your turbines—and your business—are in capable hands.