Powering Reliability. Maintaining Excellence

Comprehensive Machining Solutions

From Large Bore Machining to CNC Precision – Efficiency, Adaptability, and Speed

Comprehensive Machining Solutions by Energy Services

From Large Bore Machining to CNC Precision – Efficiency, Adaptability, and Speed

In today’s fiercely competitive industrial landscape, success is often determined by the ability to deliver high-quality, precision-engineered components on tight deadlines, while maintaining economical advantage through cost savings. Energy Services distinguishes itself as a leader in the machining sector, offering an extensive array of machining solutions that range from large bore capabilities to state-of-the-art CNC precision work, all underpinned by a commitment to faster turnaround times than competitors. This document explores the depth and breadth of machining services provided by Energy Services, highlighting their technical proficiency, diverse offerings, and the unique value proposition that sets them apart in the marketplace.

Unparalleled Range of Machining Services

Energy Services prides itself on a comprehensive suite of machining options designed to meet the requirements of diverse industries, including energy, oil and gas, manufacturing, aerospace, marine, and heavy equipment. Whether clients require robust, large-scale components or intricate, small-scale precision parts, Energy Services possesses the technical capability and experience to deliver.

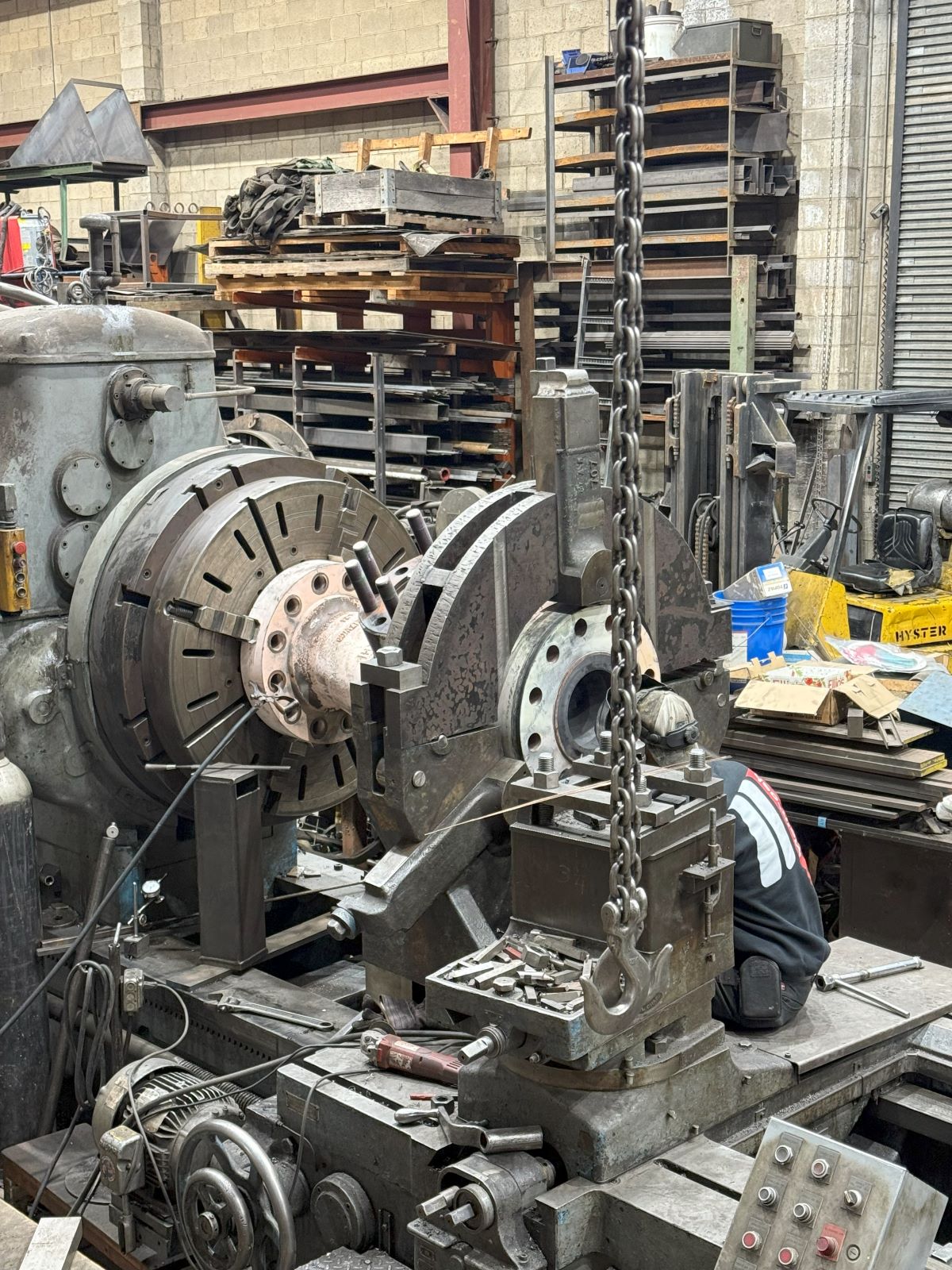

Large Bore Machining

One of the cornerstones of Energy Services’ portfolio is large bore machining. This specialized service is crucial for industries where components must handle extreme pressure, stress, and load. Large bore machining typically involves working with oversized pipes, cylinders, and casings—components essential for oilfield operations, heavy machinery, turbines, and more.

Energy Services employs advanced horizontal and vertical boring mills capable of accommodating massive workpieces. Their facilities are equipped to handle diameters stretching several feet across, and lengths extending to multiple meters. This allows the team to execute precision boring, facing, drilling, threading, and custom modifications on large-scale components with ease. Each project is executed with utmost attention to tolerances, surface finishes, and material integrity, ensuring that even the largest parts meet exacting industry standards.

CNC Precision Machining

At the other end of the spectrum, Energy Services excels in Computer Numerical Control (CNC) precision machining—a discipline where accuracy is measured in thousandths of an inch. CNC machining is the backbone of modern manufacturing, enabling the creation of complex geometries, intricate contours, and repeatable components for high-performance applications.

Energy Services maintains a fleet of the latest CNC lathes, mills, and machining centers, all operated by highly skilled machinists and programmers. Their CNC department is adept at producing prototypes, low-to-high volume production runs, and custom one-off pieces. Materials handled range from carbon and stainless steels to exotic alloys, aluminum, and engineered plastics. Each part undergoes rigorous quality control checks, leveraging advanced metrology tools to ensure every dimension and surface finish aligns with client specifications.

Complementary Machining Capabilities

Recognizing that successful component manufacturing involves more than just the primary machining process, Energy Services offers an array of supplementary services:

-

- Welding & Fabrication: Seamless integration of machined parts into larger assemblies.

- Heat Treating: Enhancement of material properties such as strength and hardness.

- Surface Finishing: Sandblasting, painting, and coating to improve durability and aesthetics.

- Reverse Engineering: Reproduction of obsolete or undrawn components using modern CAD and measurement techniques.

- Repair & Refurbishment: Restoration of worn or damaged components to extend service life.

This holistic approach allows Energy Services to function as a one-stop shop for clients, removing the need for multiple contractors and streamlining project timelines.

Efficiency and Speed: The Energy Services Advantage

Perhaps the most significant differentiator for Energy Services is their unwavering commitment to rapid turnaround. In an age where downtime can cost companies thousands or even millions of dollars, the ability to deliver on or ahead of schedule is invaluable.

Lean Manufacturing Principles

Energy Services integrates lean manufacturing principles throughout their operations. Every stage, from material procurement to final inspection, is optimized for efficiency. Innovations such as real-time job tracking, digital workflow management, and predictive maintenance of machinery help minimize bottlenecks and maximize productivity. As a result, clients benefit from reduced lead times without any compromise on quality.

Flexible Scheduling and 24/7 Operations

Understanding that emergencies and tight deadlines are common in many industries, Energy Services offers flexible scheduling, including 24/7 operations for rush jobs. Their experienced staff can pivot quickly between projects, reallocate resources as necessary, and coordinate logistics to meet even the most demanding timelines.

In-House Capabilities and Supplier Networks

By investing in a wide range of in-house equipment and maintaining strong relationships with material suppliers, Energy Services reduces dependency on external vendors. This autonomy not only improves turnaround time but also ensures better control over quality and consistency.

Quality Assurance: No Compromise

Speed is only an advantage when it is matched by quality. Energy Services has built its reputation on delivering both.

Certified Processes and Skilled Personnel

All machining operations are performed in accordance with industry certification standards, such as ISO 9001 and ASME. Skilled machinists, welders, and inspectors bring decades of experience to every project. Continuous training ensures the team remains at the forefront of technological advancements and best practices.

Advanced Inspection Tools

Quality assurance is reinforced by a comprehensive suite of inspection and metrology equipment, including Coordinate Measuring Machines (CMM), laser scanners, ultrasonic testers, and precision gauges. Detailed documentation accompanies every order, providing clients with confidence and traceability.

Industries Served

Energy Services provides solutions to a broad client base. Some of the main sectors served include:

-

- Energy and Oil & Gas: Machining of pipelines, pressure vessels, and drilling components.

- Manufacturing: Production of custom machinery parts and tooling fixtures.

- Aerospace: Fabrication of high-precision, safety-critical components.

- Marine: Machining of propeller shafts, housings, and deck equipment.

- Construction & Heavy Equipment: Repair of large structural components and undercarriage parts.

Client-Focused Approach

Energy Services places strong emphasis on open communication, transparency, and customer satisfaction. From initial consultation through delivery and after-sales support, every client is treated as a partner. Project managers work closely with customers to understand their unique needs, offer technical guidance, and provide proactive updates throughout the machining process.

Case Studies: Success Through Speed and Precision

To illustrate the impact of Energy Services’ approach, consider two representative case studies:

Large Bore Emergency Repair

A global energy client experienced a critical failure in a large bore pipeline. Energy Services mobilized a rapid response team, performed on-site measurements, and expedited the machining of a replacement section. Through round-the-clock production and coordinated logistics, the new part was delivered and installed well before the estimated downtime window, saving the client significant losses.

Complex CNC Prototype for Aerospace

An aerospace manufacturer required a high-tolerance, multi-axis machined component for prototyping. Energy Services’ CNC team developed a detailed machining plan, executed the job in record time, and provided full inspection documentation. The client was able to accelerate product testing and maintain their competitive edge in a time-sensitive market.

Commitment to Innovation

Energy Services continually invests in research, development, and new technology. By embracing automation, digital manufacturing, and advanced machining techniques, the company ensures that it remains agile and responsive to evolving industry demands.

Conclusion: Your Trusted Partner in Machining

From massive bore machining to the finest CNC precision parts, Energy Services offers the versatility, quality, and efficiency that modern industries demand. Their ability to outpace the competition on turnaround, without sacrificing accuracy or reliability, makes them a trusted partner for any machining challenge.

For organizations seeking a machining provider that delivers more than just parts, offering solutions, expertise, and peace of mind, Energy Services is the clear choice. Discover how their unmatched service and commitment to excellence can transform your next project.